What Is PI Plastic ?

Polyimide (PI Plastic) refers to a class of polymers containing imide rings on the main chain, which is one of the best organic polymer materials with comprehensive properties. Its high temperature resistance of more than 400°C, long-term use temperature range -200°C~ 300°C, part of no obvious melting point, high insulation performance, 103 Hz dielectric constant 4.0, dielectric loss only 0.004 ~ 0.007, belongs to F to H class insulation.

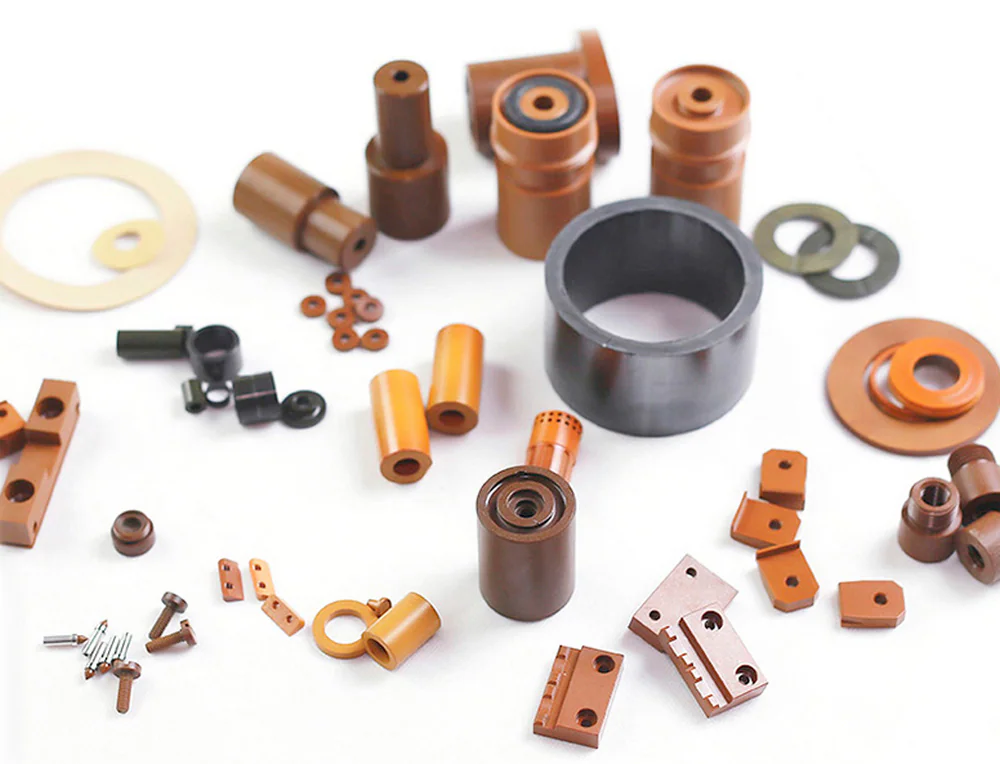

PI Plastic Products Manufacturing Company

Great Plastics is a company specializing in the production of special engineering plastic products. Provide plastic parts, rods, plates, tubes and sheets, etc. We provide a full range of solutions for customers in different industries, including research and development, design, production and sales of special engineering plastic finished parts and semi-finished profiles.

Why Use PI Plastic?

Polyimide PI is an engineering plastic that has a wide range of applications in many fields. It has high and low temperature resistance, high friction resistance, self-lubrication, high strength, high insulation, radiation resistance, corrosion resistance, small coefficient of thermal expansion, resistance to organic solvents, self-extinguishing, non-toxic and other comprehensive properties.

The Benefits

Polyimide Plastics Properties

Polyimide PI is classified as follows from the temperature resistance level:

1. PI-1003: The long-term working temperature is above 350°C, and the short-term can reach 450°C, and can be used for hot molding process.

2. PI-1006: The long-term working temperature is above 260°C, and the short-term can reach 300°C. It can be used for injection molding, hot molding and other molding processes.

3. PI-1007: The long-term working temperature is above 300°C, and the short-term can reach 400°C, and can be used for hot molding process.

4. PI-1008: The long-term working temperature is above 220°C, and the short-term can reach 300°C. It can be used for hot molding, injection molding and other molding processes.

PI Plastic Physical Properties

| Project | Unit | PI-1003 | PI-1006 | PI-1007 | PI-1008 |

|---|---|---|---|---|---|

| Density | g/cm³ | 1.45 | 1.4 | 1.4 | 1.3 |

| Tensile Strength | MPa | 62.24 | 95.00 | 127.00 | 110.00 |

| Break Elongation | % | 4.91 | 7.00 | 6.20 | 10.00 |

| Bending Strength | MPa | 149.00 | 150.00 | 94.00 | 125.00 |

| Flexural Modulus | GPa | 3.00 | 3.00 | 2.34 | 2.50 |

| Compressive Strength | MPa | 136.50 | 120.00 | 162.00 | 100.00 |

| Frictional Coefficient | _ | 0.25~0.35 | 0.25~0.35 | 0.25~0.35 | 0.25~0.35 |

| Shore D Hardness | HD | 85 | 85 | 85 | 85 |

| Notched Impact Strength | kJ/㎡ | 19.00 | 25.00 | 12.00 | 20.00 |

| Water Absorption(24H@25℃) | % | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.3 |

PI Plastic Thermal Properties

| Project | Unit | PI-1003 | PI-1006 | PI-1007 | PI-1008 |

|---|---|---|---|---|---|

| Heat Distortion Temperature | ℃ | 380 | 260 | 300 | 220 |

| Thermal Expansion Coefficient | /℃ | 5×10^-5 | 2×10^-5 | 5×10^-5 | 5×10^-5 |

| Low Temperature Resistance | ℃ | -248 | -248 | -248 | -248 |

| Maximum Service Temperature(long-term) | ℃ | 350 | 260 | 300 | 200 |

PI Plastic Electrical Characteristics

| Project | Unit | PI-1003 | PI-1006 | PI-1007 | PI-1008 |

|---|---|---|---|---|---|

| Dielectric Strength | KV/mm | 400 | 134 | 180 | |

| Dielectric Constant | _ | 2.8~3.4 | 3.0~3.2 | 2.8~3.4 | 3.0 |

| Surface Resistivity | Ω | 10^15 | 10^14 | 2.6×10^15 | 10^15 |

| Volume Resistivity | Ω·cm | 10^16 | 10^16 | 6.7×10^15 | 10^16 |

*There may be differences, the actual value shall prevail.

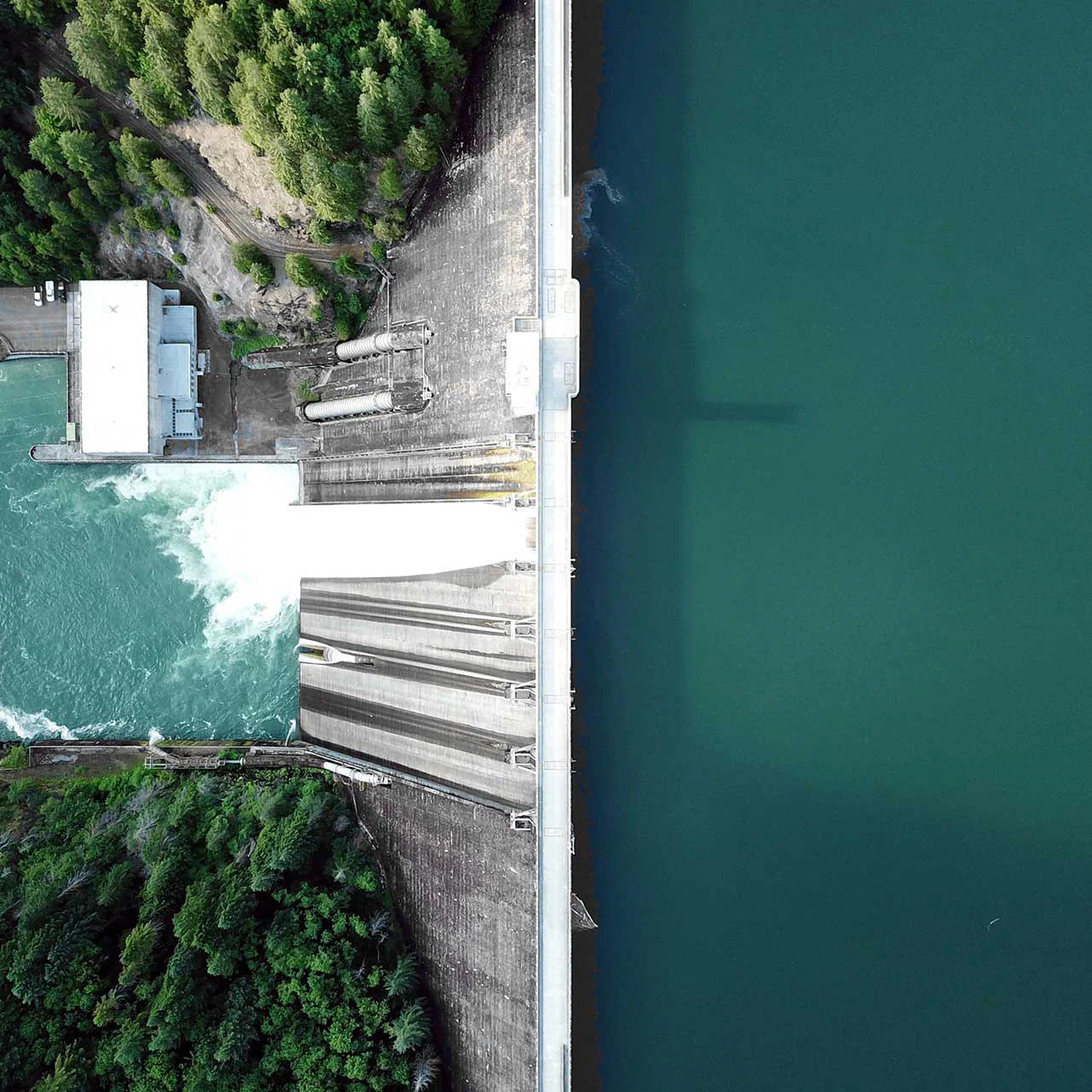

Applications Of Polyimide

Polyimide as sealing materials, structural materials, heat insulation materials, friction materials, high temperature coatings in aerospace, automotive, compressor, large motor, pump, tobacco machinery, textile machinery, engineering machinery, office machinery, electronic products, mold industry and other aspects as high temperature resistance, wear-resistant, self-lubricating or sealing parts have been widely used, won high praise from users.

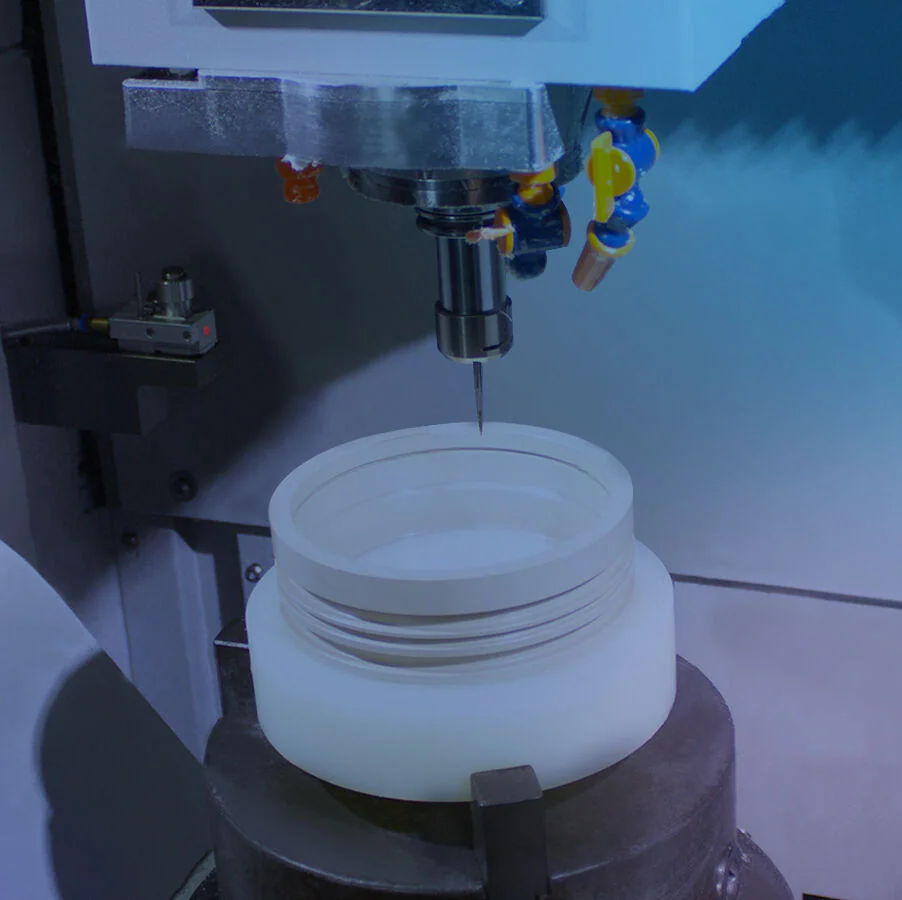

We are a precision plastic parts supplier.

Technical research and development and production of special engineering plastics, composite modified materials, and new materials.

Manufacturing Precision Parts

Let us do it for you.