What Is PAI Plastic ?

Polyamide-imide, referred to as PAI, is a class of polymers in which imide rings and amide bonds are regularly arranged alternately. It has good dimensional stability in the temperature range of 250°C and has excellent mechanical properties.

PAI Plastic Products Manufacturing Company

Great Plastics is a company specializing in the production of special engineering plastic products. Provide plastic parts, rods, plates, tubes and sheets, etc. We provide a full range of solutions for customers in different industries, including research and development, design, production and sales of special engineering plastic finished parts and semi-finished profiles.

Why Use PAI Plastic?

The working temperature is very high in the air, and it has the best dimensional stability in the temperature range of 250 ℃, excellent wear resistance and friction performance, outstanding line resistance performance, superior high energy radiation resistance performance, and inherently low flammability. High strength, high insulation, radiation resistance, self-lubricating, small coefficient of thermal expansion.

The Benefits

Available Models in Polyamide-imide Plastic

TORLON 4203 PAI 4203 (tan)

It is a kind of toughness and impact strength in PAI. Because of its inherent high temperature resistance, dimensional stability and good machinability. TORLON 4203 PAI is often used in the production of precision parts for high-tech equipment. Moreover, due to its good electrical insulation, it is widely used in the field of electrical components.

TORLON 4301 PAI (dark green)

Filled with PTFE and graphite, it has better wear resistance and lower coefficient of friction than unfilled ones. TORLON 4301PAI also exhibits excellent dimensional stability over a wide temperature range. This grade of material is mostly used in applications requiring extremely high wear resistance, such as non-lubricated bearings, seals, bearing spacers and reciprocating compressor parts.

TORLON 5530 PAI (dark green)

Filled with 30% glass fiber reinforcement, compared with TORLON 4203 PAI, it exhibits good rigidity, high strength and good creep resistance. It is very suitable for the manufacture of structural parts, supporting fixed loads for a long time at high temperatures. And because TORLON 5530 PAI exhibits excellent dimensional stability at 250 ℃, it is very commonly used to make precision parts, such as electronics and semiconductor industries. Regarding the use of TORLON 5530 PAI as a sliding part, its suitability should be carefully checked, as the glass fibers can scratch the surface.

Polyamide-imide Plastics Properties

PAI Plastic Physical Properties

| Project | Unit | PPS | PEI | PAI | PSU | PES |

|---|---|---|---|---|---|---|

| Density | Kg/m³ | 1430 | 1270 | 1450 | 1240 | 1370 |

| Bending tensile stress | MPa | – | 105 | – | 80 | 90 |

| Fracture tensile stress | MPa | 75 | – | 80 | – | – |

| Breaking tensile stress | % | 5 | 10 | 5 | 6.5 | 50 |

| Tensile modulus of elasticity | MPa | 3700 | 3400 | 5800 | 2600 | 2700 |

| Compression stress at 1% normal strain | MPa | 28 | 25 | 31 | 22 | 20 |

| Compression stress at 2% normal strain | MPa | 55 | 49 | 58 |

PAI Plastic Thermal Properties

| Project | Unit | PPS | PEI | PAI | PSU | PES |

|---|---|---|---|---|---|---|

| Melting point | ℃ | 280 | NA | NA | NA | NA |

| Thermal conductivity @ 23 ℃ | W/(K.m) | 0.3 | 0.22 | 0.54 | 0.25 | 0.18 |

| Coefficient of linear thermal expansion | ||||||

| Average value between 23 and 100 ℃ | m/(m.k) | 50×10^-6 | 45×10^-6 | 25×10^-6 | 56×10^-6 | 55×10^-6 |

| Average value between 23 and 150 ℃ | m/(m.k) | 60×10^-6 | 45×10^-6 | 25×10^-6 | ||

| Average value above 150 ℃ | m/(m.k) | 80×10^-6 | 45×10^-6 | 25×10^-6 | ||

| Maximum allowable working temperature in air | ||||||

| In a short period of time | ℃ | 260 | 200 | 270 | 180 | 220 |

| Continuous use exceeding 20000 | ℃ | 220 | 170 | 250 | 160 | 190 |

| Flammability: “Oxygen index” | ||||||

| According to UL94 (1.5/3mm thick) | % | 47 | 47 | 44 | V0 | VO |

PAI Plastic Water Absorption

| Project | Unit | PPS | PEI | PAI | PSU | PES |

|---|---|---|---|---|---|---|

| Soak in 23℃ water for 24 hours | % | 0.01/0.03 | 0.26/0.54 | 0.21/ | ||

| Connected in 23℃/50% RH air | % | 0.03 | 0.75 | 1.9 | 0.2 | 0.6 |

| Immerse in 23℃ water | % | 0.09 | 1.35 | 3.5 | 0.8 | 2 |

*There may be differences, the actual value shall prevail.

*TORLON ® RAI has the disadvantage of being extremely susceptible to various chemical damages. Steam will also degrade this material rapidly. PEEK may be the ideal material when high temperatures are required and chemical properties and resistance to hydrolysis are particularly desired.

*TORLON ® RAI has quite high hygroscopicity. If the parts work at high temperature or require high machining accuracy, they should be dried before installation. If the parts are wet and the parts work quickly in an environment above 200 ℃, it will cause thermal shock out of shape

Applications Of Polyamide-imide

PAI plastics are often used in the production of precision parts of high-tech equipment, as well as occasions with extremely high wear resistance, electronics and semiconductor industries. Products used in high temperature, high vacuum, strong radiation, ultra-low temperature conditions, aerospace, oil drilling equipment, etc.

1. Rotary compressor impeller

Because TORLON 4301 PAI can still maintain excellent performance for a long time, it is an ideal material for making sliding impellers of rotary compressors. The high material stiffness and good dimensional stability ensure that the impeller can move freely in and out of the slotted rotor without binding even at elevated temperatures.

2. Can mold

The mold made by TORLON 4301 PAI is used to support the printing of aluminum cans. This can mold has superior dimensional stability and high wear resistance, and has a long service life to increase productivity.

3. Cup welding support

These TORLON 4301 PAI holders are used in food packaging machines to complete the foil closure of plastic yogurt cups. The use of the bearing requires high wear resistance, while the temperature can reach 200°C.

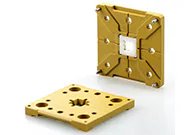

4. Chipset and socket

TORLON 5530 PAI chipset and socket for chips. Because of the dimensional stability of TORLON 5530 PAI parts over a wide temperature range, the reliability of the test is improved and the service life is extended.

We are a precision plastic parts supplier.

Technical research and development and production of special engineering plastics, composite modified materials, and new materials.

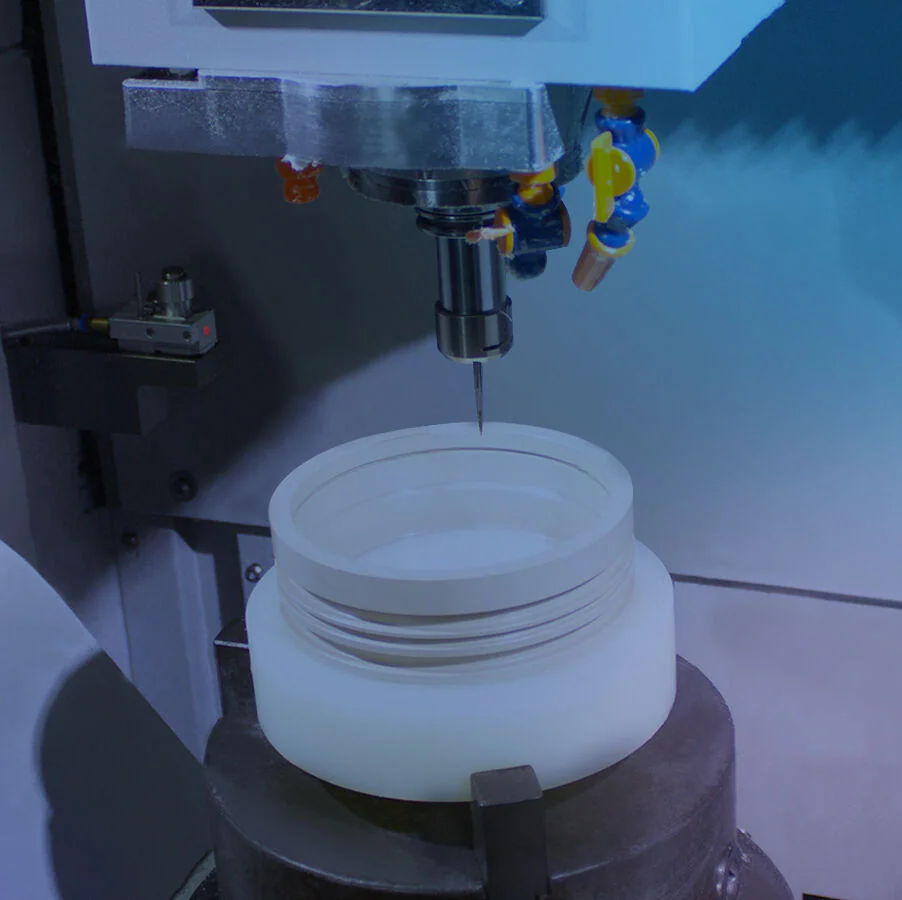

Manufacturing Precision Parts

Let us do it for you.