What Is PPS Plastic ?

Polyphenylene sulfide (PPS) is a crystalline thermoplastic resin with low crystallinity and high melting point (281°C). After stretching and heat treatment, the crystallinity and density of the fiber can be increased. PPS has good dimensional stability and high temperature resistance, corrosion resistance, radiation resistance and flame retardancy. It is suitable for structural materials, special engineering plastics and electronic appliances.

PPS Plastic Products Manufacturing Company

Great Plastics is a company specializing in the production of special engineering plastic products. Provide plastic parts, rods, plates, tubes and sheets, etc. We provide a full range of solutions for customers in different industries, including research and development, design, production and sales of special engineering plastic finished parts and semi-finished profiles.

Why Use PPS Plastic?

Polyphenylene sulfide (PPS) exhibits excellent comprehensive properties in chemical and high temperature environments, including wear resistance, high load capacity and dimensional stability. In addition, the compactness, good hardness and excellent chemical corrosion resistance of PPS profiles make it widely used in various industrial equipment, such as industrial drying and food processing ovens, chemical equipment, mechanical bearings and electrical insulation systems, etc.

The Benefits

Polyphenylene sulfide Plastics Properties

PPS profiles can be used for a long time at 220°C, and there is no solvent that can dissolve PPS below 200°C. Therefore, even at high temperatures, PPS has good corrosion resistance to inorganic acids, alkalis, and salts. In addition, PPS without adding flame retardants obtained a V-0/5V level in the UL94 flammability test, showing high flame retardancy.

PPS Plastic Physical Properties

| Project | Unit | PPS | PEI | PAI | PSU | PES |

|---|---|---|---|---|---|---|

| Density | Kg/m³ | 1430 | 1270 | 1450 | 1240 | 1370 |

| Bending tensile stress | MPa | – | 105 | – | 80 | 90 |

| Fracture tensile stress | MPa | 75 | – | 80 | – | – |

| Breaking tensile stress | % | 5 | 10 | 5 | 6.5 | 50 |

| Tensile modulus of elasticity | MPa | 3700 | 3400 | 5800 | 2600 | 2700 |

| Compression stress at 1% normal strain | MPa | 28 | 25 | 31 | 22 | 20 |

| Compression stress at 2% normal strain | MPa | 55 | 49 | 58 |

PPS Plastic Thermal Properties

| Project | Unit | PPS | PEI | PAI | PSU | PES |

|---|---|---|---|---|---|---|

| Melting point | ℃ | 280 | NA | NA | NA | NA |

| Thermal conductivity @ 23 ℃ | W/(K.m) | 0.3 | 0.22 | 0.54 | 0.25 | 0.18 |

| Coefficient of linear thermal expansion | ||||||

| Average value between 23 and 100 ℃ | m/(m.k) | 50×10^-6 | 45×10^-6 | 25×10^-6 | 56×10^-6 | 55×10^-6 |

| Average value between 23 and 150 ℃ | m/(m.k) | 60×10^-6 | 45×10^-6 | 25×10^-6 | ||

| Average value above 150 ℃ | m/(m.k) | 80×10^-6 | 45×10^-6 | 25×10^-6 | ||

| Maximum allowable working temperature in air | ||||||

| In a short period of time | ℃ | 260 | 200 | 270 | 180 | 220 |

| Continuous use exceeding 20000 | ℃ | 220 | 170 | 250 | 160 | 190 |

| Flammability: “Oxygen index” | ||||||

| According to UL94 (1.5/3mm thick) | % | 47 | 47 | 44 | V0 | VO |

PPS Plastic Water Absorption

| Project | Unit | PPS | PEI | PAI | PSU | PES |

|---|---|---|---|---|---|---|

| Soak in 23℃ water for 24 hours | % | 0.01/0.03 | 0.26/0.54 | 0.21/ | ||

| Connected in 23℃/50% RH air | % | 0.03 | 0.75 | 1.9 | 0.2 | 0.6 |

| Immerse in 23℃ water | % | 0.09 | 1.35 | 3.5 | 0.8 | 2 |

*There may be differences, the actual value shall prevail.

Applications Of Polyphenylene sulfide

Electronics: high-voltage components, shells, sockets, terminals on TVs and computers, starting coils and blades of motors, brush brackets and rotor insulation parts, contact switches, relays, electric irons, hair dryers, lamp holders, heaters, F grade film, etc.

Automobile industry: suitable for exhaust gas recirculation valves and water pump impellers, and carburetors, exhaust devices, exhaust control valves, light reflectors, bearings, sensing components, etc.

Machinery industry: used for bearings, pumps, valves, pistons, precision gears, copiers, cameras, computer parts, conduits, sprayers, fuel injectors, instrumentation parts, etc.

Chemical industry: used to make corrosion-resistant parts such as acid and alkali resistant valve pipes, pipe fittings, valves, gaskets and submersible pumps or impellers.

Engineering plastics: manufacturing auto parts, anti-corrosion coatings, electrical insulation materials, etc.

We are a precision plastic parts supplier.

Technical research and development and production of special engineering plastics, composite modified materials, and new materials.

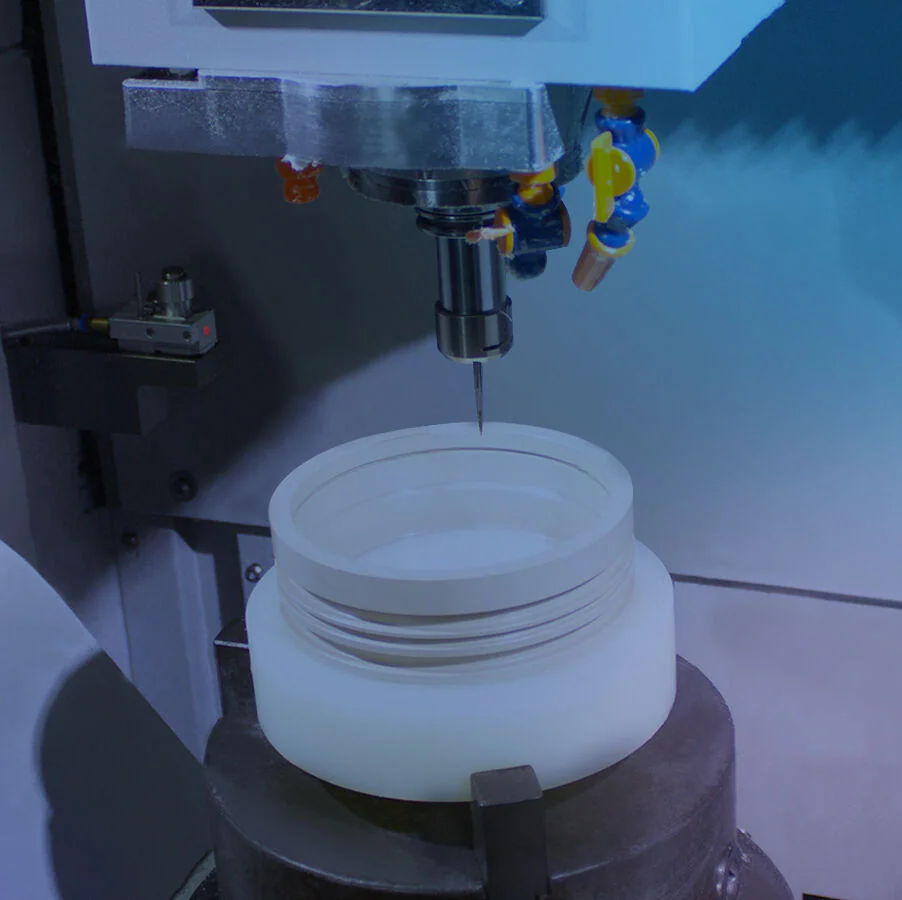

Manufacturing Precision Parts

Let us do it for you.