What Is PEI Plastic ?

Polyetherimide (PEI for short) is a super engineering plastic made of amorphous polyetherimide, which has the best high temperature resistance and dimensional stability, as well as chemical resistance, flame retardancy, electrical properties, and high strength. , high rigidity, etc., PEI resin can be widely used in high temperature resistant terminals, IC base, lighting equipment, FPCB (flexible circuit board), liquid delivery equipment, aircraft internal parts, medical equipment and household appliances, etc.

PEI Plastic Products Manufacturing Company

Great Plastics is a company specializing in the production of special engineering plastic products. Provide plastic parts, rods, plates, tubes and sheets, etc. We provide a full range of solutions for customers in different industries, including research and development, design, production and sales of special engineering plastic finished parts and semi-finished profiles.

Why Use PEI Plastic?

Polyetherimide (PEI) plastic has the best high temperature resistance and dimensional stability, as well as chemical resistance, flame retardancy, electrical properties, high strength, high rigidity, etc. Not only has high mechanical performance, but also has excellent heat resistance and chemical stability (continuous use temperature is about 180 ℃), as well as high dimensional stability and creep strength.

The Benefits

Polyetherimide Plastics Properties

Polyetherimide PEI has outstanding heat resistance (long-term temperature resistance of 180°C), exhibits good toughness and rigidity, has high hardness, good wear resistance, and outstanding electrical properties, making it very suitable for Used in electrical and electronic insulation parts (that is, various structural components that require higher strength and rigidity at high temperatures). Due to its good hydrolysis resistance, PEI is widely used in the fields of medical devices and analytical instruments. It also has excellent mechanical properties, electrical insulation, radiation resistance, high temperature resistance and wear resistance, and is microwave-permeable. At the same time, as an amorphous material, PEI has good heat insulation due to its ultra-high melting point, so PEI profiles can be used as high temperature 300°C heat insulation boards.

PEI Plastic Physical Properties

| Project | Unit | PPS | PEI | PAI | PSU | PES |

|---|---|---|---|---|---|---|

| Density | Kg/m³ | 1430 | 1270 | 1450 | 1240 | 1370 |

| Bending tensile stress | MPa | – | 105 | – | 80 | 90 |

| Fracture tensile stress | MPa | 75 | – | 80 | – | – |

| Breaking tensile stress | % | 5 | 10 | 5 | 6.5 | 50 |

| Tensile modulus of elasticity | MPa | 3700 | 3400 | 5800 | 2600 | 2700 |

| Compression stress at 1% normal strain | MPa | 28 | 25 | 31 | 22 | 20 |

| Compression stress at 2% normal strain | MPa | 55 | 49 | 58 |

PEI Plastic Thermal Properties

| Project | Unit | PPS | PEI | PAI | PSU | PES |

|---|---|---|---|---|---|---|

| Melting point | ℃ | 280 | NA | NA | NA | NA |

| Thermal conductivity @ 23 ℃ | W/(K.m) | 0.3 | 0.22 | 0.54 | 0.25 | 0.18 |

| Coefficient of linear thermal expansion | ||||||

| Average value between 23 and 100 ℃ | m/(m.k) | 50×10^-6 | 45×10^-6 | 25×10^-6 | 56×10^-6 | 55×10^-6 |

| Average value between 23 and 150 ℃ | m/(m.k) | 60×10^-6 | 45×10^-6 | 25×10^-6 | ||

| Average value above 150 ℃ | m/(m.k) | 80×10^-6 | 45×10^-6 | 25×10^-6 | ||

| Maximum allowable working temperature in air | ||||||

| In a short period of time | ℃ | 260 | 200 | 270 | 180 | 220 |

| Continuous use exceeding 20000 | ℃ | 220 | 170 | 250 | 160 | 190 |

| Flammability: “Oxygen index” | ||||||

| According to UL94 (1.5/3mm thick) | % | 47 | 47 | 44 | V0 | VO |

PEI Plastic Water Absorption

| Project | Unit | PPS | PEI | PAI | PSU | PES |

|---|---|---|---|---|---|---|

| Soak in 23℃ water for 24 hours | % | 0.01/0.03 | 0.26/0.54 | 0.21/ | ||

| Connected in 23℃/50% RH air | % | 0.03 | 0.75 | 1.9 | 0.2 | 0.6 |

| Immerse in 23℃ water | % | 0.09 | 1.35 | 3.5 | 0.8 | 2 |

*There may be differences, the actual value shall prevail.

Applications Of Polyetherimide

PEI plastics have excellent comprehensive balance properties, and are effectively used in electronics, automobiles, motors, aviation and other industrial sectors, and are used as metal substitute materials for traditional products and cultural daily necessities. Generally used in Micro/Catering, Analytical Instruments, Medical Equipment, Telecommunications, Molded Interconnects (MTD), Automotive Lighting, Aircraft Interiors, HVAC/Fluid Handling, etc.

We are a precision plastic parts supplier.

Technical research and development and production of special engineering plastics, composite modified materials, and new materials.

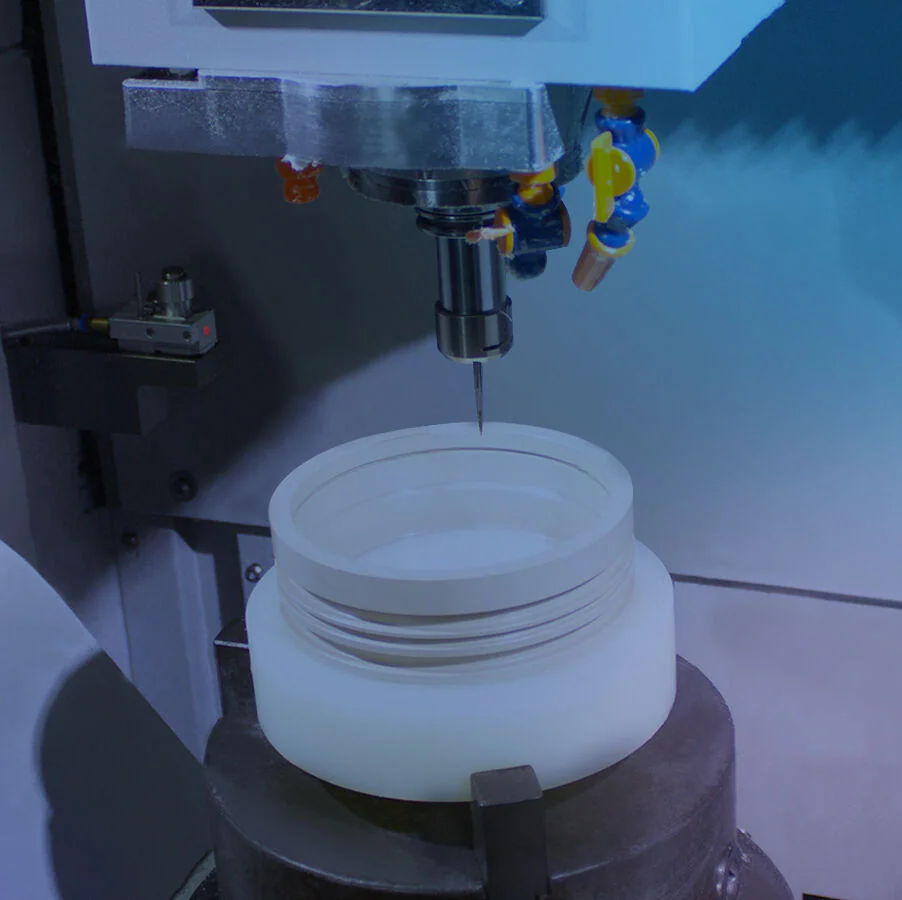

Manufacturing Precision Parts

Let us do it for you.